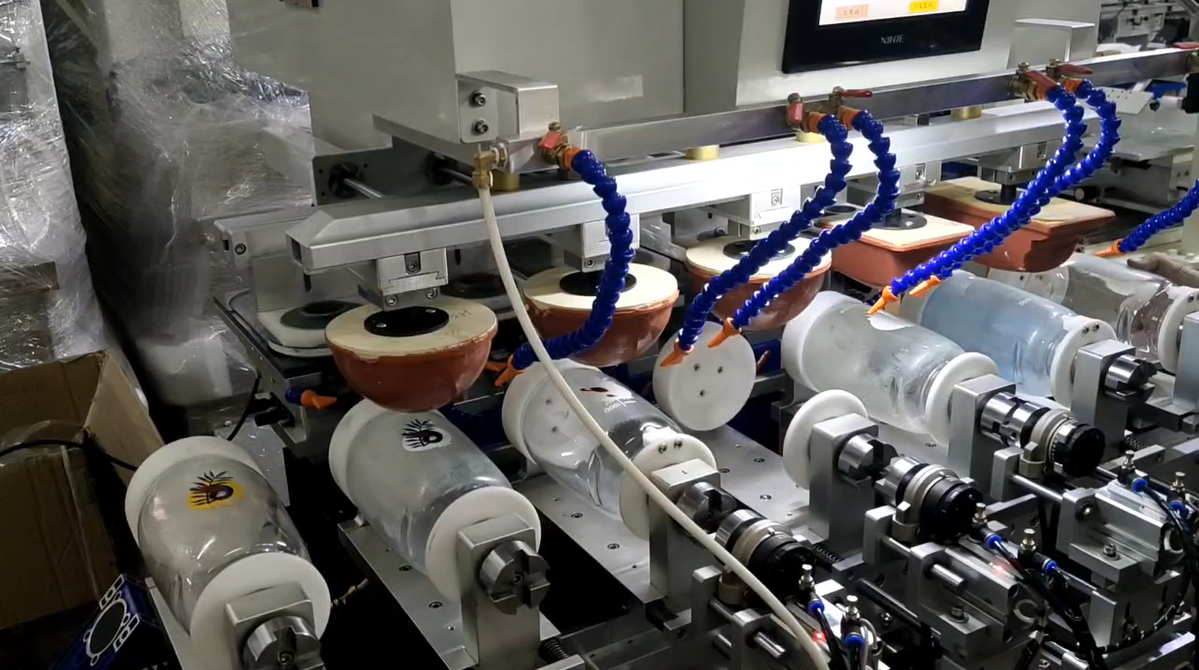

Sri Lankan daily chemical intermediary joins hands with Winneo to upgrade pad printing production line

A well-known daily chemical product distributor in Sri Lanka has multiple OEM production lines with an annual production capacity of tens of millions. With the surge in market demand for small-batch, multi-variety, high-quality packaging printing, customers are in urgent need of a stable, efficient and environmentally friendly pad printer.

Opportunities for cooperation: pain points and needs

Faced with complex multi-color LOGO , Sri Lankan daily chemical intermediaries are unable to achieve ±0.1mm color registration with existing equipment, and frequently experience misalignment, overlap or blanking; more seriously, inefficient production rhythm and high scrap rate not only greatly increase the unit cost, but also cannot meet customers' increasingly stringent compliance requirements for environmental standards. Winneo was born to provide customers with solutions that emphasize both high reliability and high precision.

Winneo Solution

Multiple color registration solutions

-According to different products and color registration requirements, it provides a variety of processes such as parallel color registration and rotation color registration, and is equipped with color mark electric eyes or visual inspection systems, with a registration accuracy of up to ±0.05mm.

- Optional intelligent turntable auxiliary device to achieve smooth transition of two-color or multi-color to meet the requirements of high-difficulty pattern printing.

Full-process technical support

- Provide one-stop service from process debugging, operation training to regular inspection, respond to maintenance requests within 48 hours to ensure production continuity.

- Accessories are directly supplied by the original factory, and key parts are shipped within 24 hours to help customers reduce maintenance costs.

Customer feedback: Trusted choice

Since the new machine was launched, customers have shown great recognition of Winneo's services: "From the request to the technical team's arrival at the factory, it took us less than a day to receive a detailed solution; after the debugging was completed, the production efficiency was directly increased by about 30%, and the scrap rate was also reduced to less than 1%." What impressed them even more was that Winneo's complete global after-sales network made them no longer worry about equipment failures, and they also felt the reliability and professionalism of their partners.

With this series of high-reliability designs, precise color matching capabilities and timely and powerful technical support, Winneo completely helped this Sri Lankan daily chemical intermediary to upgrade its production line, providing a solid guarantee for the next stage of rapid growth.

Czas pracy

Otrzymuj swoje informacje 24 godziny na dobę

Czas pekiński: Poniedziałek - Piątek 9:00-17:30